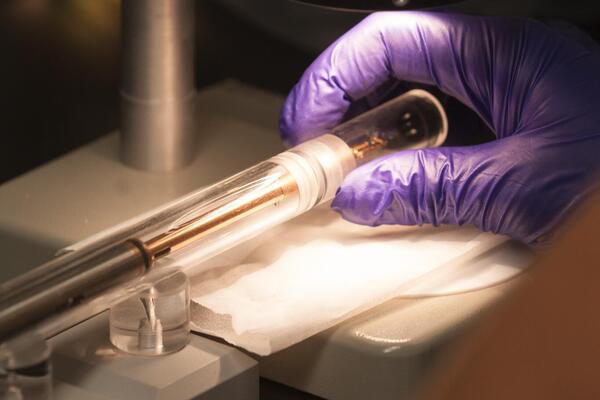

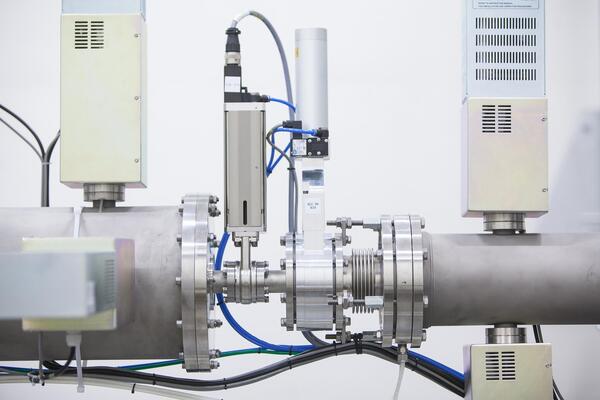

The Reactor Materials Testing Laboratory (RMTL) is an exciting endeavour for Queen's Nuclear Materials researchers, led by Professor Mark Daymond. The RMTL uses a proton accelerator to introduce damage into materials at a microscopic scale. By studying the effects of this damage on the way that materials behave we can gain insight into, and draw parallels with, the way that materials are damaged within a nuclear reactor.

Forging the way for nuclear materials research

The Reactor Materials Testing Laboratory (RMTL) is a state-of-the-art, one-story facility that was officially opened in 2015. The facility includes a proton and helium accelerator to introduce radiation damage and transmutation products into materials, mimicking the changes to materials occurring in a nuclear reactor.